Laminated production lines

Processing lines to produce laminated glass plates. Laminated glass is used in IG units and in other architectural applications for its safety features. This product is the result of two or more plates assembled with plastic foil (PVB) between them. After the autoclave process, the glass is processed on inspection lines and stacked on final racks.

Loading

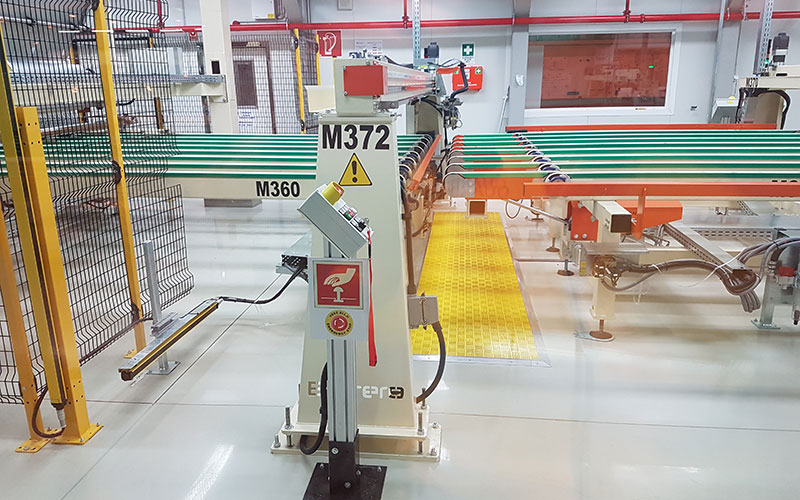

The glass plates are loaded on lines with different types of loading systems, according to glass sizes, types and numbers of racks, and cycle time of the line. Loaders can be traditional systems and/or robot solutions.

Glass transport

Synchronized conveying systems to move glass plates along all line areas. Customized solutions according to factory layout and customers’ needs. These solutions can include accumulators, LES rotators, and cutting systems.

PVB storage

Line control automatically manages the PVB storage with 6 interchangeable rolls and a self-fitting pre-unwinding system according to the size of processed plates.

PVB unwinding system

PVB unwinding system with the device to reduce air quantity between PVB and glass plate. Multi-layers unwinding possibility.

PVB trimming

Automatic bridges for the trimming of all 4 edges through a rotary disk for a continuous, fast, and accurate finishing without damaging the glass edges.

Oven and nip rolls

Modular system for pre-oven and oven with infrared lamps. The modular system gives the possibility to customize the solution according to glass type and line cycle time. Nip rolls with automatic positioning and automatic pressure set-up according to the glass thickness.

Unloading

After the pre-laminated process, the glass plates are unloaded on special racks for autoclave. During the glass unloading, the stacker or a dedicated equipment arranges the spacers to separate the glass or the packs on the autoclave rack.

Line control

Line control based on PLC platform with different levels of redundancy. Optimization system with back-up connected with lines PLCs and quality inspection system. Servers/clients SCADA system for Human interface for cutting and stacking areas with synoptic and troubleshooting functions. Report system for production and process data analysis.