Patterned lines

Patterned glass cutting lines to manage the glass ribbon from the exit of the annealing lehr. Bottero optimization system interfaced to the quality inspection system optimizes the cuts according to stacking positions and glass quality defined in the production table. The lines can be classified according to their daily production capacity, glass thickness, and sizes to cut.

Cutting

Cutting heads with latest-generation electromagnets for reliable pressure control and accurate clean cuts, for different glass thicknesses. Cut lubrication system with focused oil flow straight on scores enables a minimal quantity of lubricant on glass and it’s suitable also for using high-evaporation oils.

“X” Breakout

“X” breakout system with contrast wheels. In this position, a fast scrap eliminator can be installed.

Selvedge machine / trim deck

Transport conveyor system and breaking wheels for trim removal. The length of transport conveyors and number of breaking wheels depend on glass dimension.

“Y” dynamic breakout and separation

“Y” dynamic breakout groups and separation rolls are installed under the glass transport level. The control system automatically positions the breakout units under the glass scores and it breaks and separate lites with high repeatability and speed in dynamic during the glass transport.

Geometric inspection system

Geometric inspection system to check the glass after the breakout areas. The system verifies the glass during the transport and sends the inspection result to the line control. The line control decides to send this glass either to the cullet or to the stacker’s area.

Drop conveyors for glass plates rejection

Transport conveyor systems with the possibility, by a drop function, to send to cullet the defective glass plates. The system can be single zone, double zones, or selective zones according to the line configuration.

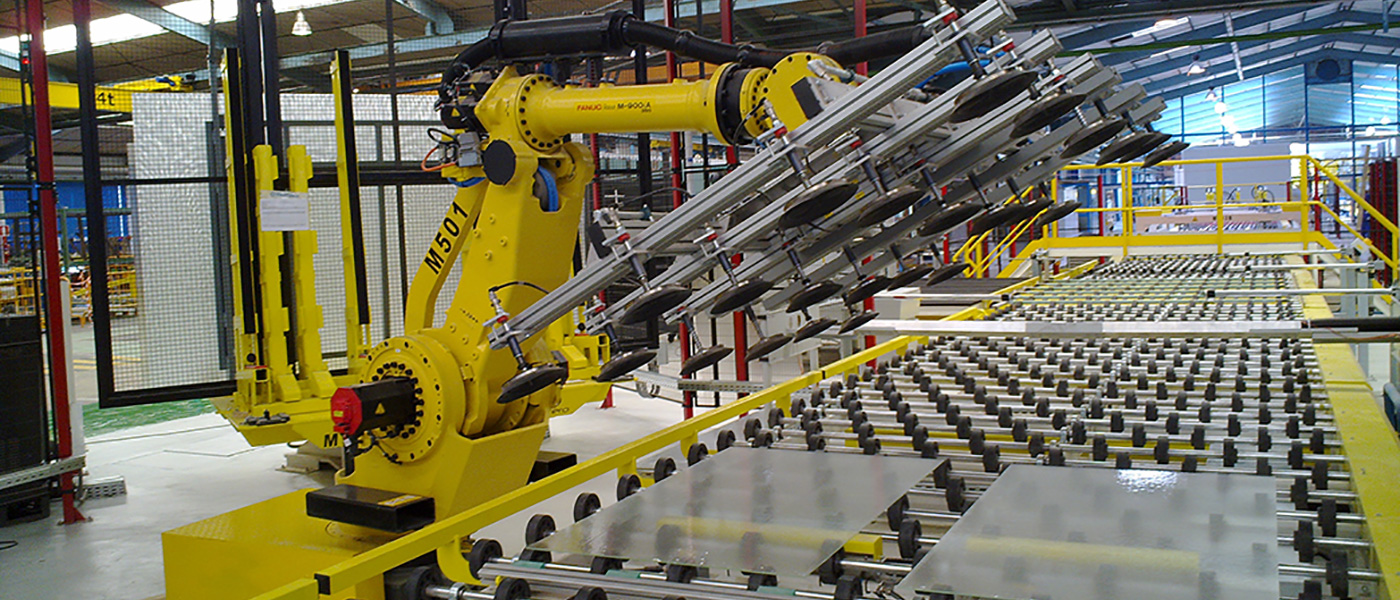

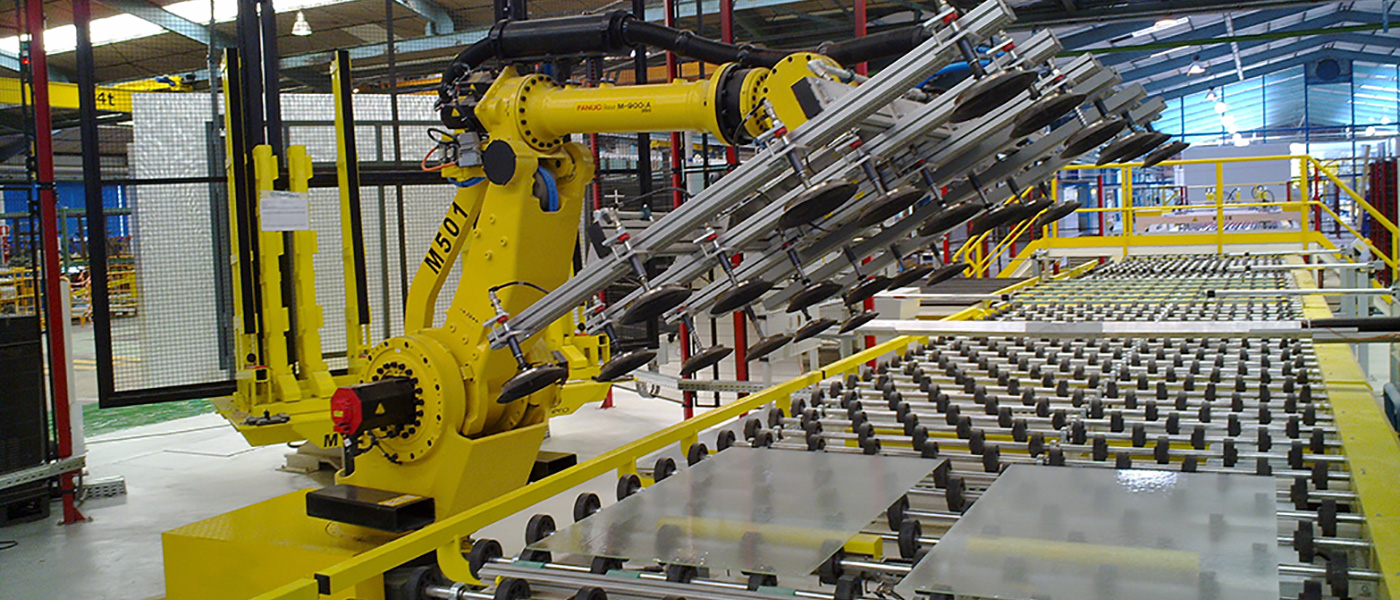

Unloading

Availability of different stacking solutions according to glass dimensions, glass contact surface, glass handling in the warehouse, and cycle time. The solutions can be either with traditional equipment or with robot systems with pick on the fly.

Line control

Line control based on PLC platform with different levels of redundancy. Optimization system with back-up connected with lines PLCs and quality inspection system. Servers/clients SCADA system for Human interface for cutting and stacking areas with synoptic and troubleshooting functions. Report system for production and process data analysis.